Smart Factory: new production logistics systems towards the IoT

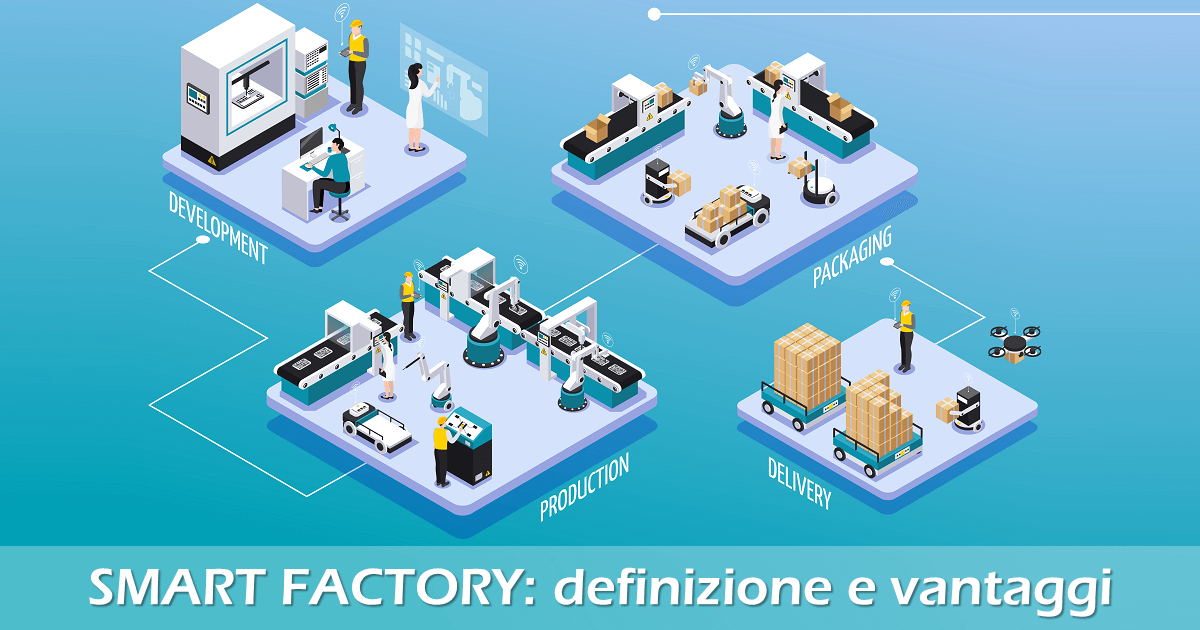

A Smart Factory is an intelligent industry where a series of equipment and systems ranging from ‘traditional’ process automation to the Internet of Things acquire data and act under the ‘control’ of Artificial Intelligence.

Smart Factory therefore means a new model of defining the plant that bases its focus on artificial intelligence as the engine of industrial processes that must become more flexible and efficient. Such new factories can be ‘studied’ in advance through CPS (Cyber-Phisical-Systems) that increase control over processes and improve collaboration between machines and people.

Above all, the company becomes ‘Agile’, i.e. capable of rapidly varying production as customer requirements change, thus ensuring that highly customised products can be produced in a short time at reasonable cost.

The Industry 4.0 paradigm is realised on an industrial level in Smart Factories where the mass of data collected is re-processed to substantially produce ‘business’ at a higher rate than in previous years.

The tools of intelligent industry

Among the main data collection tools of the intelligent industry today we have the ‘classic’ MES, which has existed on the market for many years (at least 35 years), but has now taken on new life. The MES generally takes data from plants with a direct connection to the machine (PLC, networked SCADA).

In addition to PLCs we then have the ‘novelty’ of iOT systems, basically measuring instruments that are able to communicate measured information via the network, which can be local, but is often the internet (internet of things).

These devices have made it possible to extend the collection of information outside the factory itself, but also to read very particular information such as accelerations that become very useful in the study and analysis of vibrations (which can be dangerous symptoms that signal the occurrence of a fault). Artificial intelligence then analyses the data, generates statistics, alerts for operators, allows decisions to be made, …

With the introduction of these hardware and software tools, it is finally possible to set up a Smart Factory by definition, in line with the principles of Industry 4.0 where Information Technology (information management) converges with Operational Technology (machine control and automation solutions).

According to the Politecnico di Milano, they can be categorised as follows:

– IT Solutions, which include IoT infrastructures, Big Data Analytics software and cloud computing services;

– Operational Technologies: these are represented by modular and interconnected advanced automation solutions in smart industries that provide flexibility and arrive at robotics, next-generation human-machine interfaces (HMIs), including wearable devices and Additive Manufacturing systems capable of increasing efficiency in the use of materials.

Predictive maintenance: an intelligent industry tool

Predictive maintenance is one of the most emblematic examples of the convergence between data collected through iOT systems and the use of big data and artificial intelligence software. It makes it possible to remotely control machinery and signal the need for intervention before a fault appears irreparably: IoT sensors placed on components detect operating values of the plant (e.g. temperature, pressure or the number of revolutions per minute) which are sent to local or remote processors (most often in the cloud where there is the necessary computing power) and then processed to identify any risks of failure.

The advantage is the possibility of activating timely interventions, avoiding downtimes, thanks to technical assistance or by activating automatic machine regulation. Efficiency and productivity become paramount and are guaranteed by these systems, avoiding the costs of service interruptions.

This, then, is what Smart Factory means: the benefits obtained are pervasive throughout the supply chain. By integrating IoT components into their machines, industrial machine builders can improve the services they provide by creating new maintenance contracts to provide timely service to their customers or by scheduling the timely delivery of spare parts.

The result, in adopting smart industry practices, is increased customer satisfaction and loyalty, with the possibility, in the long run, of earning the maintainer’s esteem and a future sale. For the end-user, the advantage manifests itself in the possibility of a wider choice, but above all in the continuity of production. Finally, Smart Manufacturing improves the environmental sustainability of production processes through continuous measurement and control of energy consumption.

Sygest for the Smart Factory proposes MDM (Machine driven maintenance) on the market, which goes in a logic of data acquisition, but facilitates maintenance thanks to 3D visual tools that quickly show where the problem occurred, how to solve it and which spare parts to buy.